What is aluminum square tube

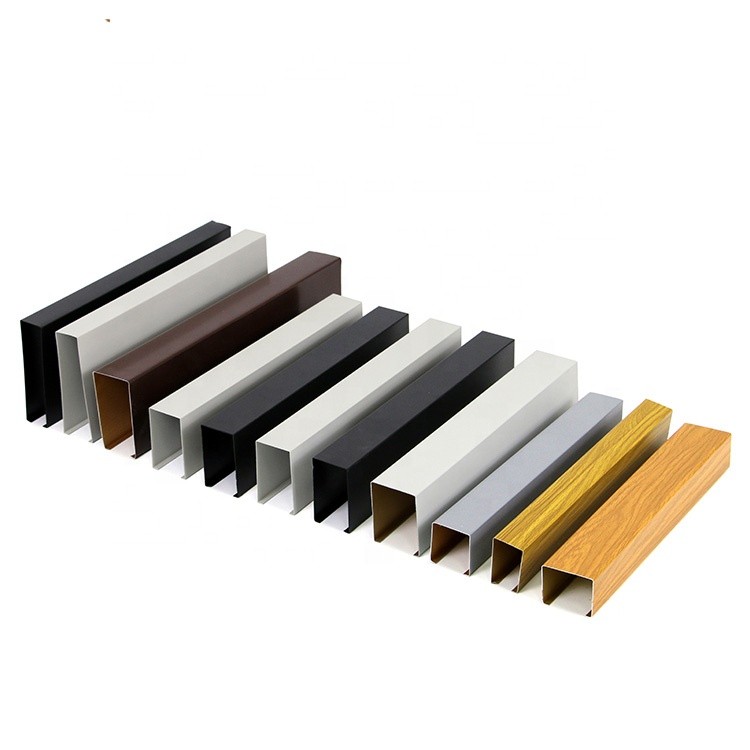

aluminum square tube(U-shaped square tube, U-shaped groove) is one of the ceiling materials produced in recent years. Aluminum square tube has an open field of vision, ventilation, breathability, and its lines are bright and neat, with clear layers, reflecting a simple and clear modern The style, installation and disassembly are simple and convenient, and it has become the main product that has swept the decoration market in recent years. It is used for concealed projects in public places where many people are crowded, which is convenient for air circulation, exhaust, and heat dissipation. At the same time, it can distribute the light evenly and make the whole space spacious and bright. It is widely used in subways, high-speed railway stations, railway stations, airports, large shopping malls, passages, leisure places, public restrooms, hotels, school restaurants, building exteriors and other open places.

Aluminum square tube Selection skills

First, the material.

There are mainly the following types of aluminum materials on the market: According to the origin of aluminum materials, they are divided into ordinary aluminum, Guangzhou aluminum, and Southwest aluminum; according to the international label of aluminum materials, they are divided into 1100, 3003, 5005 and other labels; according to aluminum alloys The strength is divided into H24, H18, etc.; according to the toughness of aluminum, it is divided into ordinary aluminum, aluminum-magnesium alloy, and aluminum-manganese alloy. Most of the ceiling materials sold on the market use ordinary aluminum, which is characterized by low strength, average flatness, strong toughness, and no deformation. Without a good substrate, it will greatly affect the service life of the aluminum square pass.

Second, surface treatment.

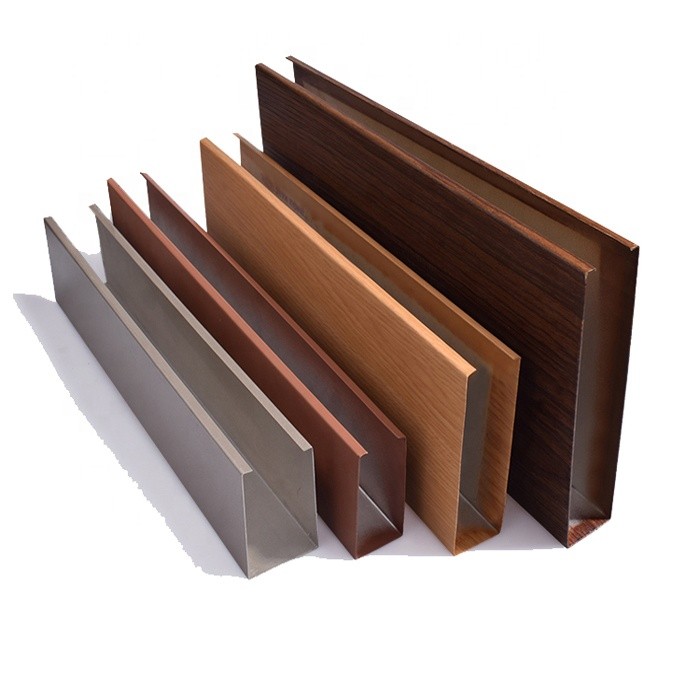

The surface treatment of aluminum square tube mainly includes the following types: spraying, baking paint, rolling, and laminating. Among them, the service life of spraying and baking varnish is short, and color difference is easy to occur. The service life of roller coating is middle. The laminated board can be divided into ordinary film and imported film. The service life of imported film can basically reach 20 years without discoloration.

Third, craftsmanship.

The so-called process is the bonding of the surface layer of the board, which is a piece that consumers have neglected. If the process is not good, the service life of the product will be greatly affected. The treatment process of aluminium rectangle tube manufacturers on the market is very different. Many small factories basically adopt the workshop style and reduce the process life. It is recommended to understand this clearly when selecting aluminium rectangle tube.

Aluminum square tube Installation plan

1. Install the aluminum trimming corners according to the same level

2. Hoist the boom and light steel keel according to the appropriate spacing. The distance between the booms is less than or equal to 1.2 meters, and the distance between the light steel keels is 1.2 meters.

3. Connect the hanging parts pre-installed on the triangle keel together with the triangle keel and the light steel keel in the vertical direction according to the spacing of the plates, and then adjust the level

4. Press the two sides of the square plate into the seam of the triangle keel in parallel, install it first, find the right angles at the two ends in the horizontal direction, and then pull the straight line to gradually buckle the plates one by one. After each row of buckles, adjust once to ensure that the plate surface is flat. , The board seam is vertical. (Note that the direction with a small hole on the side of the square plate is to insert into the seam of the triangle keel)

5. Wear gloves when buckling the board. If you accidentally leave a stain on the board, wash it off with water. It is forbidden to tear off the protective film during installation.